Efficiency is the name of the game in electrolysis

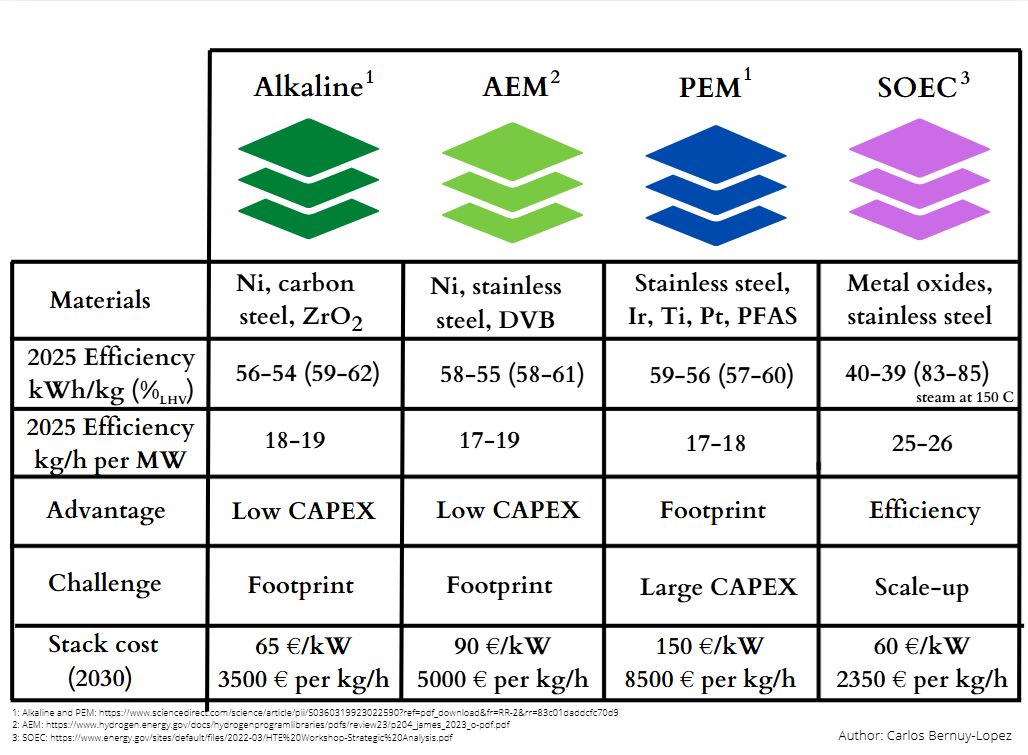

This chart (shared by Carlos Bernuy-Lopez 👏) does a great job at putting today’s main electrolysis technologies side by side.

One detail jumps out immediately: Solid Oxide Electrolysis Cells (SOECs) offer unmatched efficiency:

• 25–26 kilograms of hydrogen per megawatt-hour

• 83–85% efficiency (LHV) when using steam

• Lowest projected stack cost by 2030

At H2Electro, this is exactly why we’ve dedicated ourselves to developing fully ceramic SOEC technology. By eliminating nickel metal and relying on robust ceramic fuel electrodes, we’re pushing efficiency even further—while solving some of the toughest durability challenges in the industry.

⚡ For industries looking at large-scale green hydrogen production, efficiency isn’t just a nice-to-have—it’s the game changer that determines competitiveness.

👉 The future is clear: higher efficiency means lower costs, faster adoption, and a stronger role for hydrogen in decarbonization. And with co-electrolysis, efficiency also means turning CO₂ into valuable carbon-neutral fuels and feedstocks.

Link to Carlos’ post, read more: https://www.linkedin.com/posts/carlosbernuy_do-you-know-well-all-the-options-in-electrolysis-activity-7350783680446939137-i0Zz?utm_source=share&utm_medium=member_desktop&rcm=ACoAADoEIU0Be46G-r4cpW2cMSjnp298oWa98IY