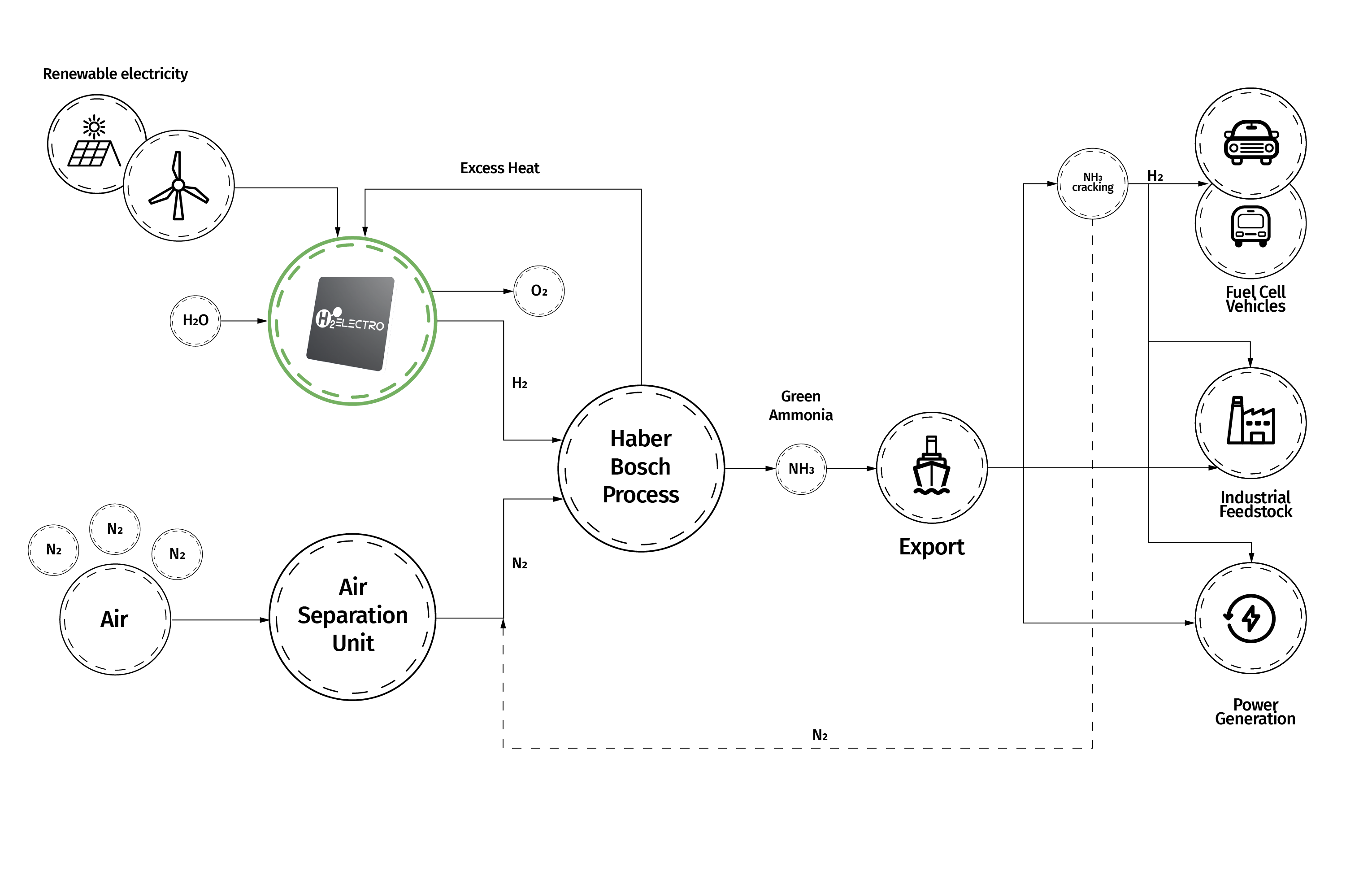

H2Electro’s SOECs are uniquely positioned to revolutionize the field of ammonia production due to their operational temperature range of 800-850°C. This temperature range aligns perfectly with the requirements of the Haber-Bosch process, the primary method for synthesizing ammonia. By operating at elevated temperatures, H2Electro’s SOECs simplify the integration of hydrogen production with ammonia synthesis, streamlining the overall production process.

Moreover, H2Electro’s SOECs offer the advantage of waste heat utilization. In the Haber-Bosch process, the exothermic nature of the reaction generates significant amounts of waste heat. H2Electro’s SOECs can harness this waste heat to heat the steam used in electrolysis, further reducing energy consumption and greenhouse gas emissions associated with ammonia production. This synergistic approach not only enhances energy efficiency but also contributes to environmental sustainability by minimizing resource waste.

- H2Electro’s SOECs enable green ammonia production by utilizing renewable energy sources.

- Green ammonia production significantly reduces carbon dioxide emissions, promoting environmental sustainability.

- H2Electro’s SOECs’ high efficiency optimizes energy conversion for ammonia production, reducing overall energy consumption.

- H2Electro’s SOEC technology offers cost-effectiveness and scalability for sustainable ammonia production.

- Green ammonia serves as efficient and sustainable hydrogen storage, supporting the transition to renewable energy