Ammonia production

💡 Did you know?

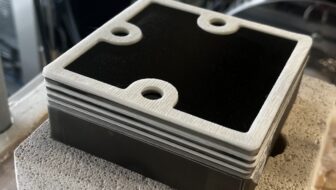

H2Electro’s fully ceramic solid oxide electrolysis cells (SOECs) and SOEC stacks offers several advantages when used for ammonia production compared to conventional methods:

👉 Efficiency: H2Electro’s SOECs have high electrical-to-chemical conversion efficiency, making them highly efficient in converting electrical energy into hydrogen gas, a key ingredient in ammonia production. This efficiency reduces energy losses in the process.

👉High-Purity, Medium-Pressure Hydrogen: H2Electro’s SOECs can produce high-purity and medium-pressure hydrogen, which can be fed into the ammonia synthesis reactor with minimal processing, improving efficiency and reducing costs.

👉 Operational Temperature: H2Electro’s SOECs operate at elevated temperatures (650-850°C), which is well-suited for ammonia synthesis through the Haber-Bosch process. This temperature compatibility simplifies the integration of hydrogen production with ammonia synthesis.

👉 Waste Heat Utilization: H2Electro’s SOECs can utilize waste heat from the exothermic Haber-Bosch process, to heat the steam used in electrolysis. This further reduces energy consumption and greenhouse gas emissions.

👉 Durability: H2Electro’s SOECs exhibit higher durability and longer operational lifetimes due to our advanced ceramic electrode materials, reducing maintenance and replacement costs.

👉 Impurity Tolerance: H2Electro’s SOECs demonstrate improved tolerance to impurities compared to competing electrolysis technologies.

👉 Modularity: H2Electro’s SOEC stacks come in various sizes and can be designed for both small-scale and large-scale applications. This modularity allows for flexibility in adapting to different production capacities.

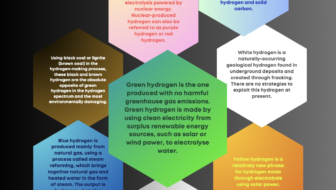

👉 Sustainability: H2Electro’s SOECs enable the production of “green hydrogen” when powered by renewable energy sources. This aligns with the demand for sustainable and environmentally friendly ammonia production, reducing the carbon footprint dramatically compared to producing hydrogen with steam methane reforming.

Overall, H2Electro’s fully ceramic SOECs offer a promising solution for cleaner, more efficient, and sustainable ammonia production, addressing environmental concerns and industry demands for greener practices.🚀