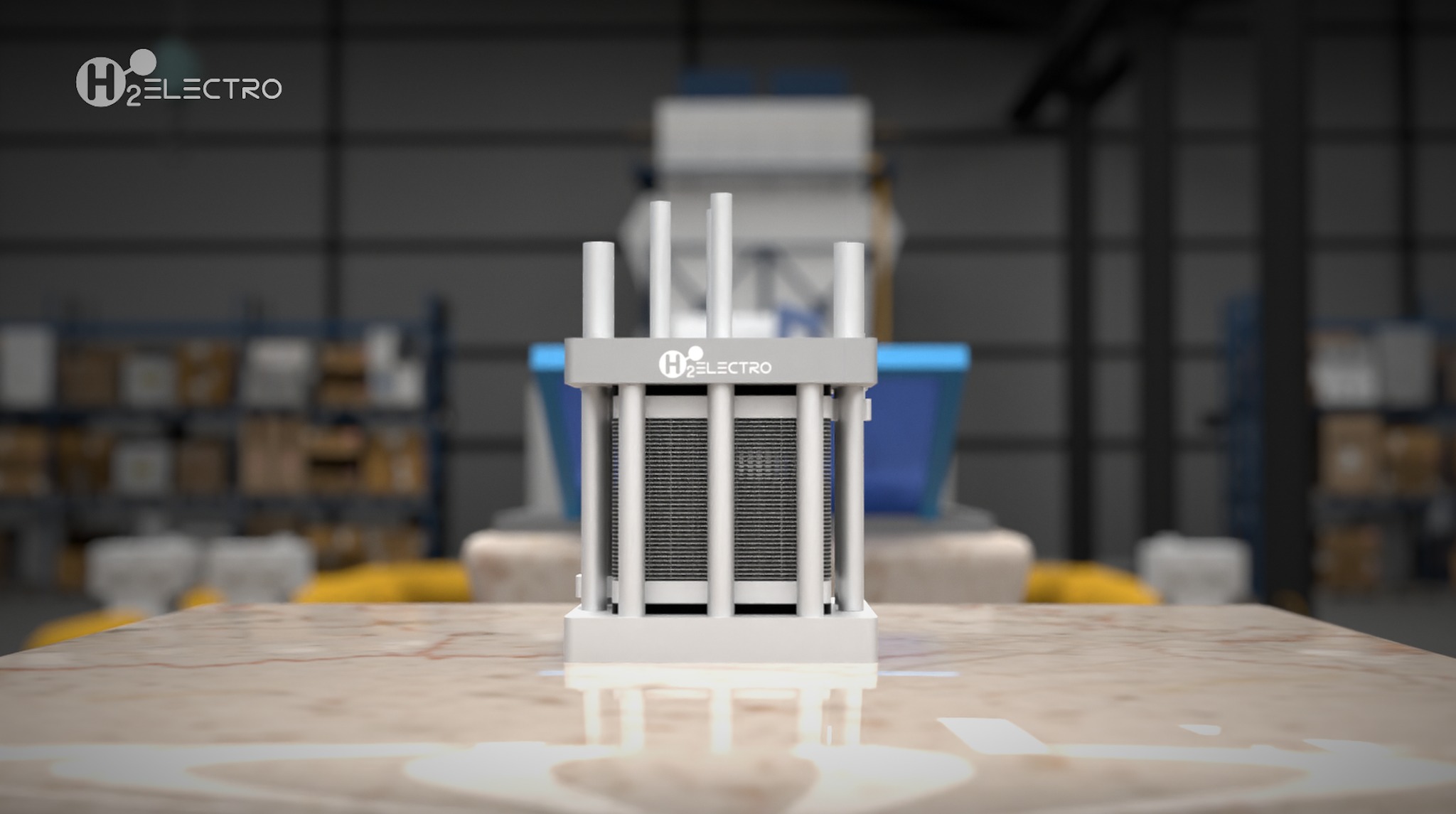

The solid oxide electrolysers

📣 Did you know that currently, hydrogen is primarily produced from fossil fuels, which results in 830 million tons of CO2 per year. The steel industry is responsible for the annual emission of 2.6 gigatons of carbon dioxide (Gt CO2). Decarbonisation of hydrogen production and the steel industry would prevent the release of more than 3.4 gigatons of CO2 into the atmosphere each year, which represents more than 9% of global CO2 emissions.

The solid oxide electrolysers (SOELs) manufactured by H2Electro make it possible to produce green hydrogen with 30% higher efficiency compared to traditional low-temperature equipment. By using SOELs, we can produce green hydrogen without using precious metals. Cheaper materials reduce the cost of the electrolyser and the hydrogen produced. Residual heat from industrial processes (such as steel production) can also be used to significantly increase the electrical efficiency of the system. Our approach is to produce 100% ceramic SOEL stacks, which are more durable than current equipment, which results in a longer life cycle and reduced support system costs.

#electrolysers #solidoxideelectrolysers #SOEL #greenfuture